GWR Diagram Y4 box van 95979

| |

| GWR box van 95979 as PLA A73 when purchased in April 1971 | Photo © BCastle 1971 |

95979 is a wagon built by the GWR theoretically to diagram Y4 and has been restored by the owners (part of the London Group of the South Devon Railway Association

). The wrought iron frame was sound, but the woodwork had rotted so badly that not even the roof was reusable. Some of the side structure also needed replacing, which was to be fun given that "T" section steel is virtually impossible to get these days.

Not much is known about 95979, but we do know it was saved by the London Group in April 1971 and arrived on the railway later that month. 95979 was built at Swindon in 1917 ( though the steel stock was rolled in 1913 ) and became Port of London Authority PLAA73. Reports that it was a steam heated banana van with an early "Instanta" three link coupling are wrong. There is absolutely no archaeology to support the suggestion of steam heat or vacuum pipes and the brake gear never had a vacuum cylinder. One instanta coupling remains, we've just got to find another (the centre link is a bent "wire" link instead of the drop forging used later on). The DC brake mechanism is far superior to the later wagon brake in some respects because it can be applied on one side and released on the other, however release is total and not progressive !

23/24/25 February 2002

Further work took place over this weekend with most of the frame stripped back to bare metal and repainted in red oxide primer. A start was made on the new steels which retain the floor and the brake gear was serviced (though some of the holes were a little larger than original).

During the stripping we found many references to the builder (GWR stamped all over the place) and an indication of 95979's build date c. 1913.

Also the DC brake wear compensating mechanism is stamped with a provisional patent number.

Easter 2002

The work over the Easter period saw both wheel sets removed for cleaning and painting. Surprisingly the journals weren't too bad and only needed rudimentary cleaning. The "Brasses" turned out to be gunmetal and are in very good condition. The archaeology continued:

the Ashburton end buffer beam was made from British Steel (Earl Dudley) rolled in October 1934 for the GWR, whilst the axle at this end was tyred in March 1917 at Swindon (the tyre having been made in Scotland) and the Totnes end was tyred in January 1919. Given the ages concerned they are in excellent condition.

Some of the new ironwork was installed and given its first coat of black paint. One of the ventilators was removed to check against the material ordered for the replacements and these were built in May over the Thomas weekend.

Update June 2002

Work since Easter progressed well with the chassis returned to "rolling" condition and the brakes reassembled. The new floor was nearly completed; a slight under provision of materials resulted in two planks being absent. This was remedied during the following visit.

The Ventilator kits were produced by the full-time staff enabling us to be in a position to assemble them. The inner vermin guards were a salutary lesson in what happens if you upset the foreman - over 100 holes and each one individually drilled ! The remaining ventilators still needed to be removed (without setting fire to the remaining wood...).

Update October 2002

Progress at this stage had been good, if a little slow; the new floor was now complete and the mothy verticals had been removed. One complete vertical had to be made and fitted; it just awaited welding to the remaining horizontal portion to complete the job. A repair section was also fabricated and it needed welding into place, probably by the full time staff. The new end Ventilators had been produced by the full-time staff, as were the inner vermin guards. These were galvanised by Medway Galvanising and waited fitting. A start was made on re-planking the sides with the side nearest the camera in the photographs above being half finished. The first plank of the remaining side and ends was also made, but not fully fitted due to the welding repairs needed.

Update February 2003

At last we'd stopped taking bits off and started on the "constructive" stages.

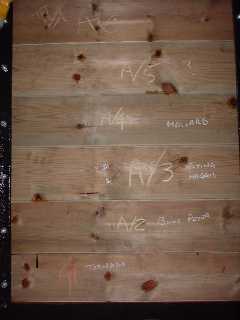

As can be seen from the following photographs good progress was now being made in fitting new wood to the wagon (even if our working instructions got miss interpreted by a humorist !).

Steady progress was being made with an anticipated completion date of late 2003.

Update August 2003

The main structure of the roof had been completed and it was just waiting for the canvas finish and final paint.

The inside walls and ceiling were painted in gloss white so we can see what we're doing and the outside received its first coat of undercoat, which meant it was now a pretty shade of pink !

|

|

| The Ashburton end awaits fitting of new ventilators | Railway Humour -Walk away and look what happens! |

|

|

| Putting in the plank retaining bolts needs precision | The sides grow rapidly where fitting is simple |

Update September 2003

The main structure of the roof was primed and the canvas finish attached, but not painted.

We wish to thank the following for the help we received:

the Bluebell Railway web site detailing how they returned to canvas;

The Sales Office Manager for T & R Williamson Ltd who make the Canvas Roof Bonding compound and Russell and Chapel Ltd of 68 Drury Lane, Covent Garden, London WC2 5SP for the prompt supply of the cotton duck canvas.

The wagon outside received its second coat of undercoat, which meant it was now a ready for the top coats (the vehicle was to have been outshopped in a Private owner livery of red and sign written "Smokeson Glass").

We still needed to make the doors, but suffered a small set back in that all the ironwork for the closing doors was accidentally disposed of by the previous owner, so we now had to make it all unless a set could be found on a scrap body.

|

|

| 95979 in Red undercoat with White Gloss inside | Ldn Gp Chair at work Note: the Colour combination |

|

|

| Finishing touches to the inside walls | Modern electrics have been installed |

Update September 2004

The roof had been completed but we still hadn't tested it for waterproofness because we still had no doors.

A pair of doors were fabricated from field seasoned oak and tanalised pine boarding.

The photo below gives an indication of how the finished van will look once we make and hang the other pair of doors.

Because we never had the closing (right hand) doors we would have to fabricate the ironwork unless GWR fittings can be found from a scrap van body.

|

| 95979 in Buckfastleigh running shed, one side nearly complete |

|

| March 2005, the other side nearly complete |

Update March 2005

During January and March 2005 we finished machining the oak we purchased for the remaining pair of doors.

These were now assembled, fitted to the wagon, primed and undercoated as can be seen in the photograph above.

We purchased two large posts to form the door heads which when fitted would complete the woodwork, so once we had the door furniture completion of the project would be in sight.

|

|

| New Oak top rail in position | Gavin reattaches the lock securing pin |

|

|

| John fixes the lock staple | Finished door (well almost..) |

Update September 2005

Progress on the wagon had been slowed due to diversions onto 1645 and RM1872 but we got a little closer to completing one side of the wagon by installing the top lintle and temporarily fitting the door furniture. As you can see from the photographs above it was beginning to look like a wagon again (just compare with the top of the page). Frighteningly it was exactly a year since we first hung these doors!

Update December 2005

|

| 28th November 2005; Buckfastleigh side nears completion. Photo: Richard Elliott |

To our surprise 95979 found itself in the side of "A" shop following the shunt to move 3803's tender to "B" shop and so progress on finishing it speeded up. The Staverton side door head was fitted in February and the doors themselves rebated in March. The remaining door furniture was added and we thank the workshop staff for their assistance in making the missing bits such as a dozen No. 18 countersunk wood screws.

As can be seen from the following photographs the van was now rather smart. All that was left was the signwriting on the outside and completion of the storage system inside. The signwriting was to be a plain GW in black but the van is red because we rebuilt it as a private owner "covered goods wagon" We had been hoping for sponsorship but nothing materialised.

95979 was scheduled to take part in the end of May Gala when it ran in the GWR goods train.

|

|

| The ironwork is picked out in black | The door protection plates are added |

|

|

| All the door furniture is in place - finished! | The number plate is now rather smart |

The trouble with stating one's finished is that the wagon will get moved to Totnes to make way for another project (Loco 33002)!

At the time the wagon still needed its sign writing (owner, running number, tare and gross weights).

|

| 95979 basks in the sunshine at the head of a goods train in the Totnes Littlehempston bay |

Some more work was done on the wagon, namely the painting of the internal racking and the signwriting on the outside. When we restored 276 to original condition we removed the racking installed during the conversion to a breakdown support vehicle. This redundant racking was then installed into 95979 and we have subsequently found that the racking was from a GWR tool van - we have half a set but don't know which van it was from.

Since the sponsorship deal didn't materialise we decided to replicate the GWR livery of the 1890's (not correct for this wagon but correct for a red wagon!).

|

| 95979 in 1890's style GWR livery (if only the class 20 & concrete sleepers were absent !). |

95979 has recently received a new layer of Robbins Timber Elite 6mm marine plywood to the roof and a new layer of cotton duck canvas – see September 2003 above for details.

The canvas has had two coats of primer undercoat and three coats of light grey gloss paint.

The metal hoops have been repainted in T & R Williamson Ltd spec 81 “Black for underfames”

The Staverton side oak door head has been repaired with a new top plate glued onto it and the Buckfastleigh side has been replaced completely with a new one made from seasoned oak.

The Buckfastleigh side locking door has had a new bottom rail fitted. Both it and the Staverton side locking door are due new diagonal braces.

The peeling paint is being removed and the surface prepared for painting in T & R Williamson Ltd spec 81 RAL2001 “Orange Red” starting with three coats of “Express Red” undercoat.

Once repainted it will be signwritten as Port of London PLA A73.

|

| 95979’s new canvas roof |